|

||||||||

D SEAL TUBE FITTINGS: A VERSATILE FITTING FOR MANY APPLICATIONS

|

MAXIMUM WORKING PRESSURES (PIPE THREADS ENDS) Pressure ratings for fittings that have both tube fittings and pipe thread ends are determined by the end connection with the lowest pressure rating. The pipe end pressure ratings chart lists pressure ratings for male and female pipe thread ends.

To determine working pressure ratings in accordance with ASME B31.1 Power Piping for 316 stainless steel, multiply psi by 0.94; for carbon steel, multiply psi by 0.75. Brass ratings remain the same. SAE PRESSURE RATINGS Pressure ratings are from SAE J1926/3.

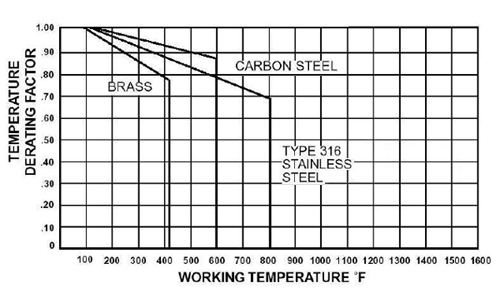

DERATING FACTORS FOR ELEVATED TEMPERATURE APPLICATIONS  Pressure rating procedure 1. For applications involving service at elevated temperatures, the pressure rating must be multiplied by an appropriate temperature derating factor obtained from the temperature derating chart above. 2. Carbon steel tube fittings not normally recommended above 600°F/315°C. 3. Type 316 stainless steel tube fittings not normally recommended above 800°F/426°C. 4. Brass tube fittings not normally recommended above 425°F/218°C. 5. These working pressures are not necessarily valid for system components. Prudent system design requires that all other system components be evaluated for their specific proper pressure capabilities. |

|||||||